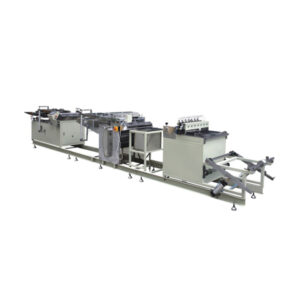

SEGT-600 Full-auto Rotary Pleating Production Line

₨ 2,500

Spin-on Oil and Fuel Filter Elements and Component

This machine is especially designed to pleat the fuel; oil and heavy duty air filter elements.

Description

[tabs layout=”horizontal” nav_color=”accent2″ left_color=”accent8″ right_color=”accent1″]

[tab icon=”” title=”General Description”]

This machine is especially designed to pleat the fuel; oil and heavy duty air filter elements.

[/tab]

[tab icon=”” title=”Components”]

1.Pleating speed: 0-30m/min

2.Max pleating width: 600mm

3.Min pleating width: 30mm

4.Max pleating height: 50mm

5.Min pleating height: 10mm

6.The roller sizes can be customized

7.Heating power: 6Kw

8.Temperature control: normal-300 degree

9.Total power of the line: 7.5Kw

10.Air pressure: 0.6Mpa

11.Power supply: 380V/50Hz

12.Machine weight: 1100kg

13.Machine size: 6000mm*1100mm*1200mm (L*W*H)

[/tab]

[tab icon=”” title=”Specifications”]

[/tab]

[tab icon=”” title=”Features”]

1.The pre-slitter uses pneumatic slitting blades and it is simple for regulation and evenly pressed.

2.Six sets of rolls are equipped in the same round table which can be easily changed and suitable for producing in different specifications.

3.The machine can also make embossment on paper which is especially suitable for the heavy duty air filter; 4.The process of the machine is auto counting, pleating, pre-heating and forming.

5.This machine has stainless steel conveyer device, so the filter paper is pleated much more evenly and smoothly.

6.It is easy to operate through the computer control.

[/tab]

[/tabs]

Reviews

There are no reviews yet.